| Short Øglænd history. Øglænd bicycle factory 1949 | ^ back to TEMPO main. |

|

Mainpage of ● Norway. ● Tempo.

|

● Norwegian links. ● Advertisements guide.

|

● Norlett motorplenklippere. ● Lappesaker, Jonas Øglænd. ● VIKING A/S Askim Gummivarefabrik.

|

● Sett på Ekebergmarkedet. ● Mopeden, årets slager. ● Kronblom kjør moped. ● Jeg tar mopeden. ● Håndbok Sachs 50/4. |

[41-60] DBS sykkler. [1949] Vi besøker en stor norsk sykkelfabrikk. [1949] Øglænd history, article bicycle factory. ● Teknikk for Alle. Norsk vidundercykkel.

|

| Short Jonas Øglænd moped history. |

|

During the fifty's there were was restrictions in Norway in the numbers of vehicles (mopeds) a factory / producer could sell.

Øglænds therefore sold their products under other (bicycle) manufacturers name (more than usual in this "branch").

| ARROW | Erling Sande, Oslo. |

|

| T15 | ||

| ERLA | Erlands Maskinforretning, Bryne. | |

| T20 | ||

| FAVORIT | Artur Syvertsen Vennesla Kristiansand. | |

| T25 | ||

| INO-PED | Ingvald Nielsen, Oslo. | |

| T30 | ||

| MAMMUT | Sønsterud Sykkelfabrikk, Oslo. | |

| T35 | ||

| OLYMPIC |

Axel Bruun Trondheim sold Øglænd bicycles, moped's and motorcycles under the name Olympic. For a period the mopeds were mounted at their own bicycle factory. |

|

| T36 | ||

| PANN | Rogaland Auto, Stavanger. | |

| T37 | ||

| SPEED | A. Erlandsson: Skien Cykkelfabrikk, Skien. | |

| T40 | ||

| SPRINT |

Lønne i Sandefjord. Tempo Victoria was sold under the name "Sprint" (ca.1953). |

|

| T45 | ||

| STANDARD | Beck & Bertelsen, Skien. | |

| T50 | ||

| SVITHUN |

Maskinhuset A/S Stavanger. Produced mopeds to the seventy's.: Puch. |

|

| T55 | ||

| TAMBAR |

Lefstad Sport, Trondheim. Production of their own moped Nidaros (late fifty's). Lefstad Sport also sold Raufoss mopeds a period. |

|

| T60 | ||

| TRYGG | P.T. Helleberg, Lillehammer. | |

| T65 | ||

| WESTBY | O. Westby, Kongsvinger. |

|

Øglænd factory at Sandnes, Norway.

|

Jonas Øglænd founded his firm in Sandnes ±1868. It was for its time, "a typical country store" where you could buy almost everything. His sons' interest in cycling led to the importation of German (argentur 1892) and American bikes. They also ran a repair shop for bicycles. The property where the bicycle production started in purchased ±1906.

This was the start of an extensive bicycle, moped and motorcycle production the following years, from 1960 to 1982 Øglænd produced 2 11 700 mopeds and motorcycles. 1962 there were 60,000 mopeds registered in Norway (Norway registration on mopeds (license plates), it was / is a little more hp on Norwegian engines compared to the Swedish mopeds. In Sweden their was no registration of mopeds).

1985 was the last year it was manufactured moped parts, moped production ceased 1987. The production unit was sold to Portugal, where it was manufactured Corvette moped 1987-94. 1989 Øglænd sold DBS to Monark AB, Varberg Sweden. DBS would remain as his own bicycle brand. Øglænd in Sweden (agent.). Øglænds moped model's were sold under the name DBS in Sweden. One of Øglænds bicycle names in Norway.

The main warehouse in Sweden was in Tidaholm. SIMONS-RADIO-TV-SPORT-AB. Model's sold in Sweden from 1962: Øglænd-DBS-Swing, Øglænd-DBS-Swing Sport, Standard DBS Sport 3022 (type: Panter), Øglænd-DBS-Saxonette, DBS-Saxonette 3033, DBS Safir 3034, DBS Handy, DBS Panter, DBS Safir automat, DBS Hercules and DBS Amigo. |

| 1960 - Some TEMPO vehicles. |

|

|

Moped Tempo-Lett Corvette 240, med den verdenskjente Sachs 50 motor. Leveres med kickstart eller pedaler. Se ogsa årets nyhet, mopedscooteren Tempo-Lett Corvette de Luxe.

|

Transport - Dei ideelle kjøretøy for varetransport. Kassen rommer en nyttelast på ca. 100 kg, og motoren er den driftssikre SACHS 125 ccm. |

Tempo «Moto-Cross» - overlegent største poengscorer ved norgesmesterskapet i både molo-cross og terrengløp i 1959. |

Motorsykkel. Den dominerende motorsykkelen på norske veier. Utmerkede kjøre- egenskaper og mange tekniske finesser. Tempo har SACHS motor - 125 og 175 ccm -- kraftig og sikker. |

|

Jonas Øglænd A/S 1868 - 19686 100 år.

|

|

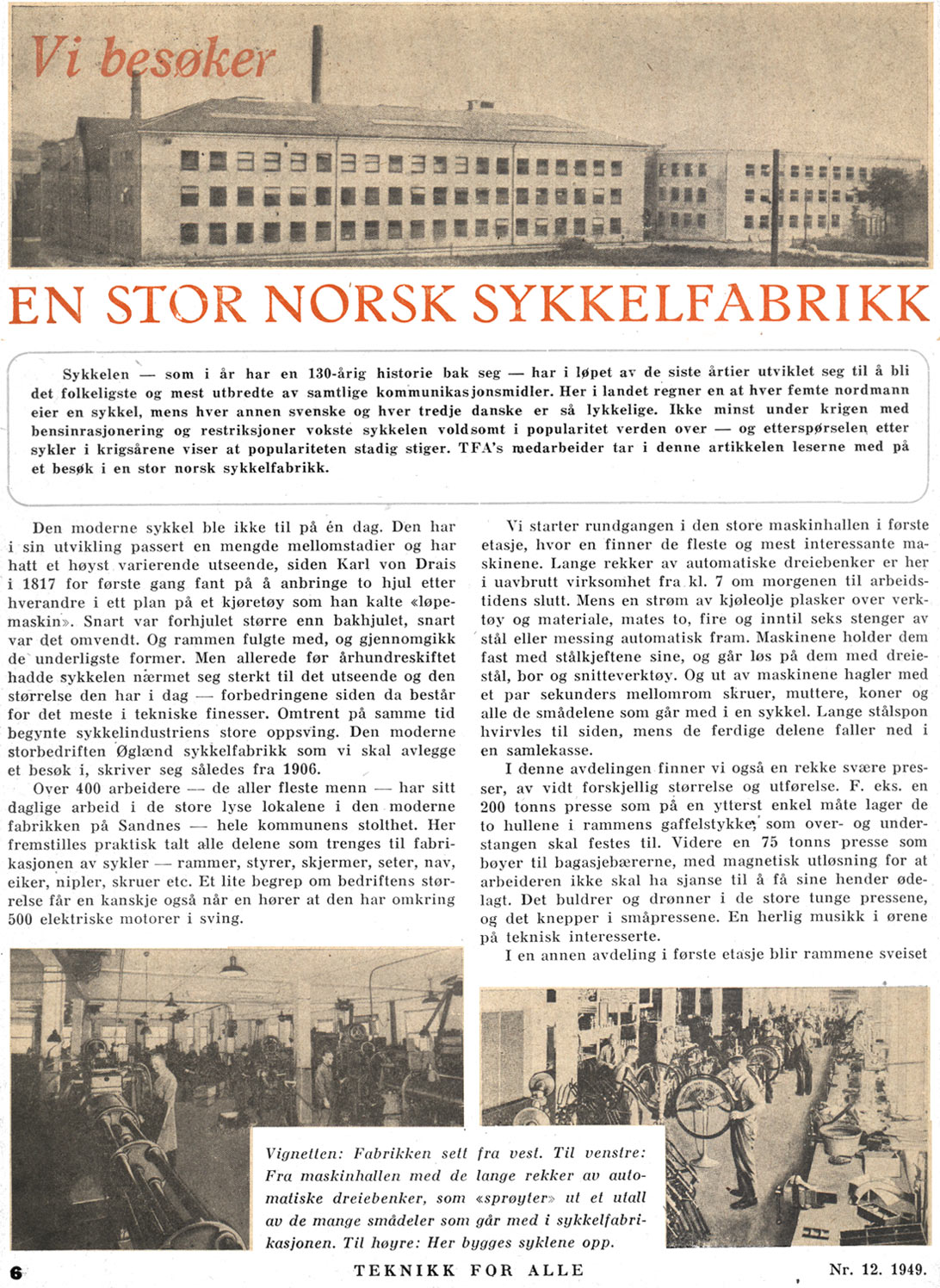

| 1949 | TEKNIKK FOR ALLE Nr. 12. Factory seen from west. | [Norwegian - Google english.] |

|

|

|

We visit a large NORWEGIAN BICYCLE FACTORY.

The bike - which this year features a 130-year history behind it - has in the past decades has evolved to become the most popular and most widespread of all means of communication. In this country expect a that one in five Norwegians own a bike, while every other Swedish and one in three Danish are so happy. Not least during the war with petrol rationing and restrictions grew the bike tremendously in popularity the world over - and the demand for bicycles in the war years shows that the popularity steadily rising. The modern bicycle was not in a day. It has in its development passed a number of stages and has had a highly variable appearance, since Karl von Drais in 1817 for the first time decided to put two wheels in a row in one plane on a vehicle which he called "running machine". Soon, the front wheel larger than the rear wheel, and sometimes the reverse. The frame came with, and underwent the strangest forms. But even before the turn of the century had the bike approached greatly to the appearance and the size it is today - the improvements since then, consists mostly of technical features. Around the same time began cycling industry's big boom.

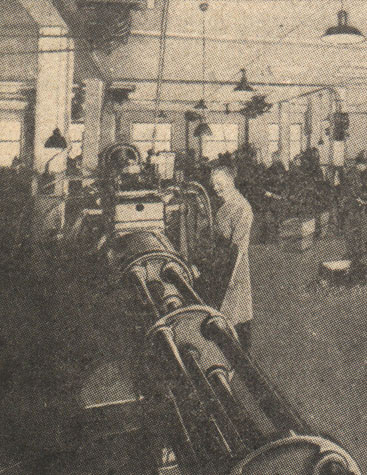

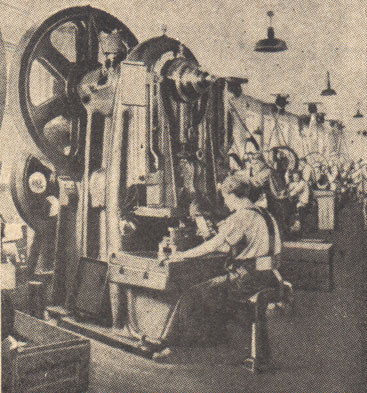

The modern large enterprise Øglænd bicycle factory that we should pay a visit to, arises thus from 1906.Over 400 workers - most of them men - have their daily work in the major light stations in the modern factory in Sandnes - all municipal pride. It produced virtually all the parts needed to manufacture the bikes - frames, boards, screens, seats, hubs, spokes, nipples, screws eat. A little idea about the company's size is perhaps also when one hears that it has about 500 electric motors. we start the tour in the great machine hall on the first floor, where one finds most interesting and most maskinene. Long rows of automatic lathes are in continuous operation from at. 7 am until the end of workday.

While a stream of cooling oil splash of tools and materials, fed two, four and six rods of steel or brass automatic way. The machines keep them stuck with their steel jaws, and tackling them with a rotating steel, drill and cut tools. And out of the machine guns with a couple of seconds screws, nuts, cones and all the small parts that go into a bike. Long steel shavings whirled to the side, while the finished parts falling into a "box". In this department, we also find a number of large presses, of very different size and design. A 200-ton press that on a very simple way, they make two holes in the frame fork piece, 'as the upper and lower rod should be attached to. Furthermore, a 75-ton press that bends to the luggage carriers with magnetic release that the worker will not have a chance to get their hands broken. It rumbles and booms in the large heavy presses, and it snaps in the small presses. A beautiful music in the ears of technical interest.

In another department in the first floor are welded frames - electric. The two parts to be welded together and placed simply in the welding apparatus, the power is on, and a couple of seconds later removed - fully completed. Soon bike frame finish, directed and controlled and applied plant number. Already during the war exceeded this number 500 000, and not be made since then. In the same department work is done on all part in the manufacture of bicycle frames, forks, controls. In the The grinding area - which is also located on the first floor - ground to see the parts before further processing, nickel plating, chrome plating or lacquering. A portion of the work performed as hand grinding, but a number of grinding machines are also used. Here you can see a semi-automatic grinding machine that takes advantage of the large sprocket in cycling gear. And here see a grinding machine with a series of loosely suspended grinding machines, which ensures that even the twisted board is completely grinded.

The production of wheels and monitors are no less interesting. Wheel material comes in the form of profile steel in coils from the steel works. Coil up in a rolling machine, and on its course through this band get its rim profile and rounded to the diameter of the rim should have. The entire coil is after rolling led on to a cutting machine that cuts the bend in rim lengths, which then goes on to the electric welding machines. But still need the rim undergo many operations - grinding, straightening and hole punching - before they can be passed on to paint or nickel plating department. The presentation of the screens is done much the same way.

Coatings is performed by different methods. Some parts, such as. frames are dipped in large vats with asphalt varnish and hung on racks. Other parts, such as. fork which usually has a chrome-plated field, is spray painted. Staff ring takes place on the other hand to hand with the ordinary brush, and places heavy demands on it to mount the narrow lines pe rim and frame. For a long tunnel - where the temperature is up to 220 gr. - There is room for a total of seven units, each of which contains 36 frames or 72 wheels or towards 200 screens. In this fire burned look into the paint - and the parts are shiny again approx. 1 hour later.

Chrome plating process, it is also interesting e follow. The parts are first a careful prepared in the electrolytic bath, and the put into the nickel baths. A few of these are large revolving baths, one with thousands of liters fluid content which parts go their tour in. After nickel plating is polished sections up to high gloss and then to the chrome plating bath, where they get their chrome coating.

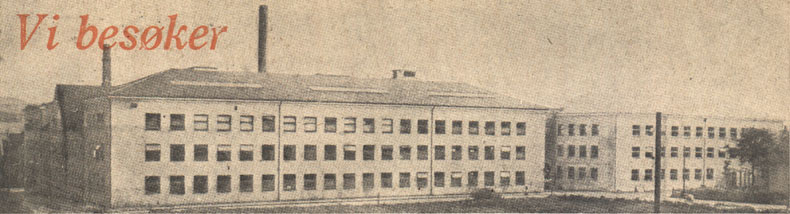

Eventually together so all the finished parts in mount hall on the second floor. Some parts are then already assembled together, for example. hubs, brakes, seats, pedals and wheels. The assembly work is performed essentially by the industrious woman's hands, while frame and bicycle assembly are reserved for men. The frame and parts together with bicycle installers who stands in a row, busy at their stands. During testing, inspection and still control, built the bikes up until they are fully completed and forwarded to the packing department.

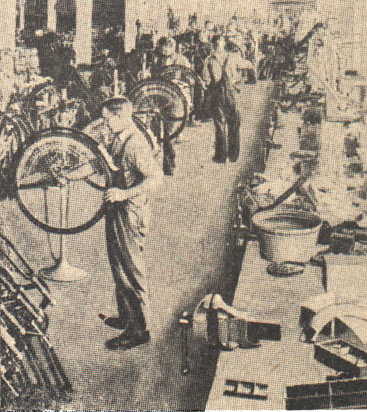

One would not get a full impression of the modern bicycle factory on a not even paying a visit to the motorcycle division and take a look at the production of the only motorcycle - a so-called <lightweight, at 125 kb.cm. The production of the individual parts, frames, wheels, boards, etc. is done by the same principles and to some extent also in the same machinery as the manufacture of bicycle parts. This section is therefore simply an assembly department. The operation here is nowhere near full, but the reason for that is only the country's foreign exchange situation. The engines must in fact imported from abroad - specifically the UK - and the government can not, under current conditions perform sufficient quantities of foreign currency for such imports.

<-- Scene from a race rides in Christiania in 1884, with the famous or infamous "Veltepettere". The rings were at this time still made of iron bands. It was a complete revolution on bicycle manufacture area when the Irish veterinarian John B. Dunlop in 1888 constructed its air ring. Dunlop said that he got the idea for the invention of his son who had taken a rubber hose from his laboratory, pumped it up and put it on his three-wheeled bicycle.

|